What is a prefinished wood veneer?

(Read on, it’s pretty simple).

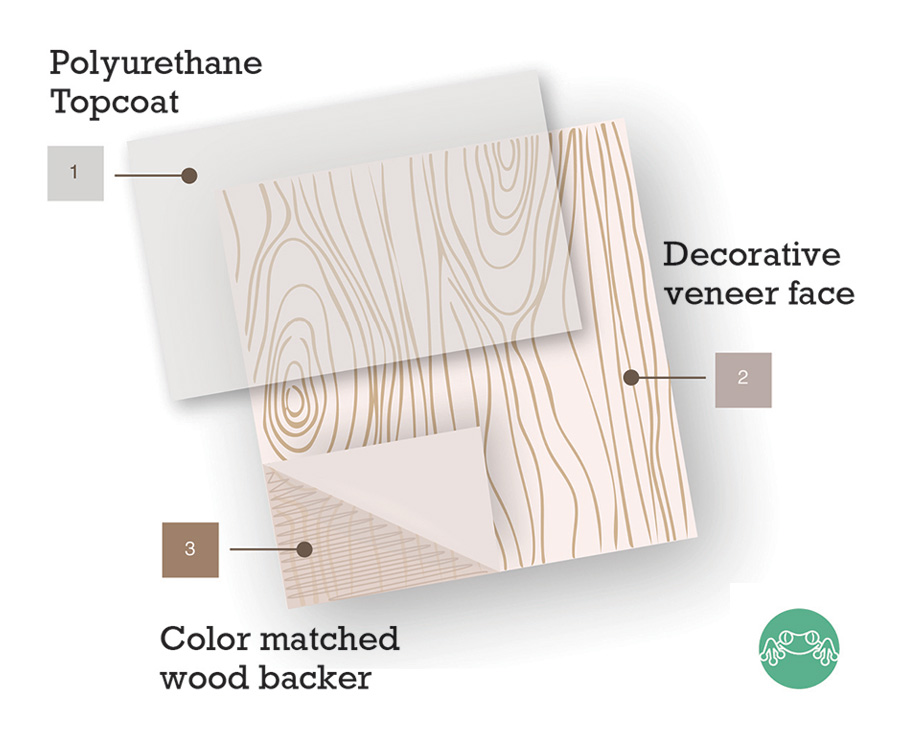

A prefinished wood veneer is an easy to use, ready to apply beautiful wood veneer sheet that is really made up of two functional wood sheets, a decorative face and a flexible, color matched wood backer.

Every sheet of Treefrog Veneer showcases the rich, soothing and timeless beauty of real wood. It’s not printed, it’s not plastic. It’s real. Place a sample of Treefrog next to a laminate that’s not real wood and see the dramatic difference.

Plus Treefrog offers consistent selection in design spaces of any size, which means you can specify or order, say, 100 sheets of Treefrog and every sheet will look almost exactly the same. This isn’t usually the case with natural veneers and is important in large spaces, and multi-location projects like retail stores, restaurant chains, hotel rooms, cabinetry and anyplace where consistency in appearance is important.

The Decorative Face:

For Treefrog, this is a beautiful, composite, engineered or “recon” wood veneer. This process uses faster growing and more commonly occurring tree species to replicate almost any wood species, real or imaginary. It’s an impressive process and technology that guarantees consistency, sheet after sheet. Besides, all that, it’s really beautiful. Treefrog represents a decidedly European aesthetic; a variety of oaks, walnuts, and more.

The Wood Backer:

New in 2023, the wood backer replaces an industry standard laminate backer. The benefits are many. First, it’s a color matched backer- white oak is backed by a sand colored backer, black oak by a very dark grey backer etc. – which eliminates the dreaded laminate edge, that dark line no one likes. Second, it’s more flexible and easier to handle, which wood working professionals love. The backer is applied perpendicular to the veneer face, this cross graining gives the veneer layers more stability and balance and creates a wood veneer that’s both strong and flexible.

But wait it’s also prefinished:

As always, Treefrog remains a prefinished wood veneer with a polyurethane topcoat. The topcoat is applied in a controlled manufacturing environment. This can save on fabrication costs. Plus, there are no doubts or worries about how the wood will look when finish is applied. It already is. What you see is what you get. A consistently beautiful, oftentimes breathtaking sheet of real wood that’s consistent beautiful.